We have developed an automated application focused on companies with several operations and continuous format changes who have high operation costs and a large accumulation of equipment on floor. We aim to lower these costs and investments by offering a automated finished product handling system by LGV/AGV. Our proposal prevents the installation of packaging equipment at each machine, and allows for a smart internal logistic system for material storage.

Closure Handling

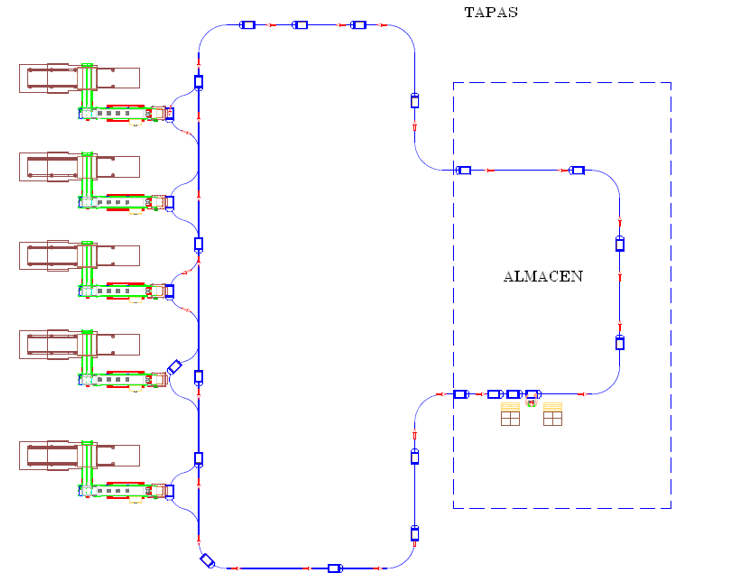

We developed a SW and HW platform to control mission execution and anti collisions. In the following example you can see X amount of closure injection modules, where each module includes a conveyor soft drop system, a product cooler and a high precision scale. When our SW detects that a weight station is about to arrive at the predetermined weight, it executes a mission:

- The AGV/LGV Takes an empty box from the box former

- The AGV/LGV positions it underneath the weight module and waits for the scale to release the product.

- The AGV/LGV leaves the module and takes the box to the finished product warehouse.

- The AGV/LGV Stands by for next mission.

Preform Handling

We have developed a proposal for automated preform production and logistics as well. In this scenario, you can appreciate X amount of preform injection modules, each including a conveying system that receives the parts and then feeds the preform to boxes or containers by weight or counting injection cycles, due to the precision required for part inventory. In this example, each injection module has two LGV/AGV stations, and each station fills one box/container at a time with the indicated amount of product. The missions are executed, and empty boxes are delivered to each station, as full boxes are removed and sent towards the finished product warehouse as the SW indicates.

We guarantee quality product handling by receiving the product under the press with a soft drop conveyor and cooling the product by filtered room temperature air. This application avoids unnecessary equipment and boxes on floor, the equipment delivers the product directly onto the AGV/LGV that then moves the container to the ware house. The operation does not require operators and is made to work in a lights off operation. The mission control platform is controlled by out SW, and communicates mission information with the MRP or ERP by an OPC server.