DESCRIPTION

The TEC Preform Orienter is an efficient, highly automated, preform orienting system.

There are six components to the TEC Preform Orienter, which work together to handle Preform and provide you with a flawless operation:

- The Gaylord Dumper

- The Storage Hopper

- The Loading Conveyor

- The Orienter

- The Neck guide

- The Singulator

SUMMARY

The Gaylord Dumper deposits the Preform in to the Storage Hopper. The Loading Conveyor then conveys the Preform to the Orienter. Finally, the oriented material travels through the Neck Guide and is fed out by the Singulator into the blow molding machine, quality inspection machine or any type of Preform machine for its further processing.

PREFORM RECEPTION IN THE STORAGE HOPPER

The Gaylord Dumper works pneumatically and is equipped with electrical controls that allow its operation. The main function of the Gaylord Dumper is to deposit the Perform into the Storage Hopper. Once the Gaylord is in position and secured to the Dumper, the operator can easily turn over the content into the Gaylord.

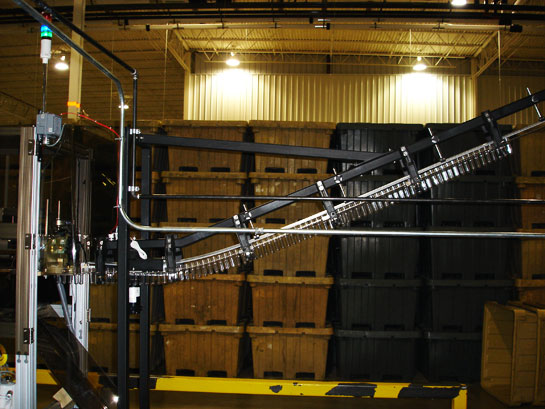

ELEVATING OR LOADING CONVEYOR

The Elevating or Loading Conveyor features a control panel that allows variable speeds. Speed Variability is crucial for the proper working of the system as it allows control of the amount of Preform being fed into the Orienter.

ORIENTER

The Orienter is the heart of the TEC Preform Orientor. It consists of a Stainless Steel Hopper with two 3.5 meter long and 3.5” wide Stainless Steel Rollers at its bottom, which are constantly turning in opposite directions (outward rotation from 800 rpm to 1000 rpm). The Orienter receives the material from the Loading Conveyor. The constant turning of the Rollers plus the degree of inclination of the Orienter causes the Preform to place itself vertically. The Rollers can be adjusted to different speeds and openings depending on the dimensions of the Preform being processed.

Preform that is not properly oriented is deposited back into the Storage Hopper through the reject shute.

The Orienter is equipped with sensors to prevent preform overflow inside the rollers.

NECK GUIDE

The Neck Guide consists of a high density polyurethane guide made of low friction UHMW guides, with a Stainless Steel interior, through which the preform slide down by gravity from the Orienter into the Singulator. The Neck Guide opening and inclination angle are adjustable to the size and type of preform being processed.

SINGULATOR

The Singulator feeds the machine at the output of the TEC Preform Orientor. The preform can be delivered and separated at different speeds by adjusting the Singulator’s DC Drive Speed.